Üretim Modülü

Üretim Modülü

Nitro Smart Üretim Modülü

Teknolojinin gelişmesiyle beraber ürünlerin özellikleri, tasarımı ve kullanılan materyalleri gelişmektedir. Bu gelişmeyle beraber ürünlerin üretim sürecinde kullanılan materyallerde değişik gösterebilir. Bu durum sonucunda işletme sahipleri ürünlerin üretiminde daha dikkatli olabilecek bir süreç izlemelidir. Çünkü ürün üretim sürecindeki yapılan bir hata işletmeye maddi zararlar verebilir. ERP yazılımı işletmenin bu durumla karşılaşmaması için Üretim Modülü yazılımını geliştirmiştir.

Türkiye’nin En Gelişmiş Üretim Modülü

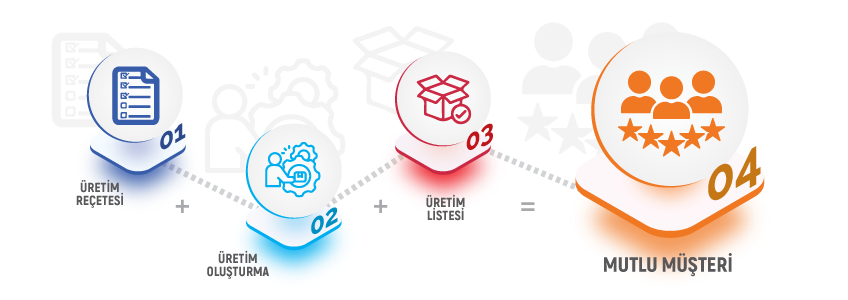

Üretim Modülü işletmeler için kullanımı kolay ve üretim sürecini hızlandıracak bir yazılıma sahiptir. Bu Modül 3 aşama ile gerçekleştirilen bir yazılıma sahiptir. Bunlar,

Üretim Reçetesi: İşletmenin bir ürünü üretmek için ihtiyacı olan materyalleri belirler. Bu belirlenen materyaller sistem üzerinden girişi yapılır. Örneğin, bir işletmenin arıza tespit cihazı ürettiğini düşünelim. İşletme arıza tespit cihazı üretiminde arge ve yazılım gibi materyallere ihtiyacı vardır. İşletmedeki yetkili Üretim Reçetesi oluşturduğunda ilk olan ürünü yazacaktır daha sonra ürüne ait materyallerin sayısını belirterek sisteme yükleyecektir. Buna ek olarak, Üretim Reçetesi yazılımında işletmelere arayüzü daha anlaşılır hale getirmek için ürün üretmede kullanılan materyalleri sisteme girdikten sonra otomatik olarak üretim süreci şema ile gösterim oluşmaktadır. Bu durum işletmelerin daha hızlı ve daha kolay bir şekilde üretim yapmasına destek olur. Böylece işletme yetkilisi bir ürün için üretim reçetesine sahip olmuştur.

Üretim Oluşturma: İşletmedeki yetkilisi olan kişi tarafından üretilmek istenilen ürün, ürün reçetesinden seçilir ve kaç adet üretmek istediğini ilgili bölüme yazmaktadır. Bunun sonucunda sistem otomatik olarak entegre sistemi sayesinde üretim reçetesindeki yazan bilgilerle üretilmek istenen adeti birleştirir. Bunun sonucunda işletme yetkilisi tarafında gereken materyal sayılarına erişim sağlanır.

Üretim Listesi: İşletme Yetkilisi ürettiği ürünün fotoğrafını yükler, ürün adeti belirtir ve ürün kg bazlı mı veya metre bazlı mı gibi özelliklerini belirterek ürününü listeler. Bu süreçten sonra depo ile bağlantılı olarak ürüne onay verilerek ürünün depodaki stokunda güncelleme yapılır.

Üretim Modülü tek bir sistem üzerinden işletmenin üretim sürecinin daha sistematik bir şekilde ilerlemesine yardımcı olur. Buna ek olarak, bu modül sayesinde işletme daha doğru ve daha basit bir üretim gerçekleştirmiş olur. İşletmelerde üretim süreci ERP sisteminin sahip olduğu Üretim Modülüyle dijital ortamdan yararlanılarak daha güvenilir bir özelliğe sahip olmuştur. Bu durum satın alma süreci için etkili bir yazılımdır. Çünkü satın alma sürecinde güvenilirlik ve kalite çok etkilidir. Bu durumda sistem üzerinden oluşturulan üretim şeması işletmeler için daha dikkat çekici bir yazılım haline gelme niteliği taşımaktadır.