Stok ve Depo Modülü

Stok ve Depo Modülü

Nitro Smart Stok ve Depo Modülü

Modernleşme çağında gelişmekte olan ve gelişen işletmelerde depo ve stok yönetimi çok önemlidir. İşletmeler stok bilgisi, tedarik süreci ve depo durumları gibi konularda güncel bilgilere ulaşmayı isterler. Çünkü bir işletme için minimum ürün miktarına sahip olmasına rağmen teslimat sürecinin hızlı olmasını hedef alır. Bu durum müşteri için bir güven ağa oluşturabilir. Depo ve stok yönetiminde manuel girişi tercih eden işletmeler için zamandan tasarruf etmek mümkün değildir.

Çünkü manuel giriş bir işletme için zaman ayırması gereken, hata yapılmaması için stok sayımında dikkatli olması gereken ve tedarik sürecinde sık sık takip gerektiren bir sistemdir. Bu durumda ERP yazılımı Depo ve Stok Yönetimi programı ile şirketler için daha kolay ve pratik hale getirmiştir. Böylece şirketler daha kısa sürede, daha az vakit harcayarak depo ve stok programında güncel takibe sahip olacaktır.

Türkiye’nin En Gelişmiş Stok Ve Depo Modülü

Depo ve Stok Programı isterseniz depo bazında isterseniz de depodaki ürünler bazında sizlere seçim imkânı sunmaktadır. Bir işletme bir ürün satın alımından sonra ister ürünü şube deposuna geldikten sonra program üzerinden tek tıkla farklı depoya veya farklı depolara transfer sürecini gerçekleştirebilir. İşletmenin ürün transfer aşamasında ilgili depoya ulaştığı anda yetkili kişi sistemden onay vererek şubeye ürünü teslim aldığına dair bir bildirim göndermektedir. Böylece ürün Depo ve Stok Programı üzerinde mevcut konumu güncellenir. Buna ek olarak işletmenin ürünü satın alma sürecinden sonra, Depo ve Stok Programı üzerinden ürünün seri numarasıyla beraber sisteme girmektedir. Bu şirket için ürünün satın alma sürecinden sonra hangi depolarda olduğunu, satın alma işleminin ne zaman gerçekleştiğini ve kim tarafından satın alındığına dair güncel bilgilere istediği her an erişim sağlayabilir.

Ayrıca işletme bir ürünün hangi depoların stoklarında olduğunu ve ürün miktarlarına güncel olarak erişim sağlamaktadır. İşletme sistem üzerinden stok rapor ekranını inceleyerek ürünün toplam satış miktarını kontrol edebilir. Böylece işletme stoklarındaki güncel duruma sahip olur. Bu durumda işletme manuel girişten daha az vakit harcaması sonucunda daha basit bir şekilde ürünün stok miktarını öğrenmiş olur.

İşletme ürün kontrol işleminden ürünlerin depodaki raf sürelerini görebilir. İşletme ürünü satın aldıktan sonra satış ve muhasebe modülüyle entegre olarak bir satın alma süreci izlemektedir. Yani satış ekibi tarafından satışı yapılan bir ürün muhasebe ekibi tarafından onay verilmesi gerekir muhasebe ekibi ürünün satışına onay verdikten sonra ürünün stok miktarı düşer. Böylece tek bir program üzerinden zaman tasarrufu yaparak tek bir tıkla işletme ürün satışını deposundaki ürün stokuna yansıtmış olur.

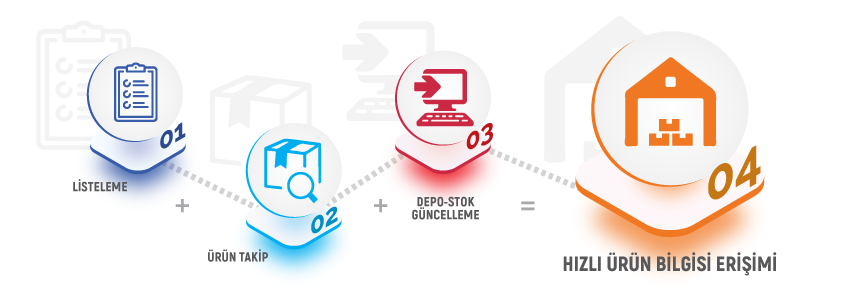

Depo ve Stok Programı bir işletme için zamandan tasarruf ve her zaman güncel bir bilgiye erişim sağlayan bir programdır. Böylece işletme için çok avantajlıdır. İşletme program sayesinde tek bir tıkla ürün stoku güncellemesi, ürün satışından sonra stoktan düşmesi ve ürün transfer sürecindeki takibini yapabilir. Ayrıca program üzerinden barkod tanımı yaparak barkod okuyucuyla işletme tarafından adet ürün takibi yapabilir. Böylece işletmenin dijital platform üzerinden daha hızlı ürün bilgisine erişim sağlamasına yardım olur. Basit ve hızlı bir arayüze sahip olan bu sistem işletmeler için büyük bir avantaj sağlamaktadır.